The raw material silo uses an underground silo in this site, eliminating the tedious process of frequent feeding by forklifts; the frequency belt feeder and the equipment main machine current are interlocked in real time to ensure that the equipment performs in the best state; the main equipment is strengthened type, effectively absorb the vibration generated during operation of the equipment. It is of high capacity, stable operation, low voice and robust performance.

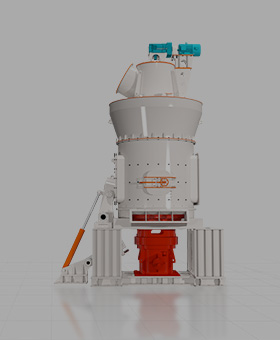

Limestone which meet the feed specifications are uniformly and quantitatively sent to the YGMXO190-Q4 European type strenght grinding mill by a variable frequency belt feeder for grinding. The qualified products are collected by the bypass double cyclone powder collector, and then lifted by the bucket elevator to the finished product bin. The unqualified materials fall back to the main machine for re-grinding, and the entire system is in a closed cycle. It is equipped with a pulse bag dust collector to collect excess gas and fine dust in the return air to achieve dust-free operation in the workshop.