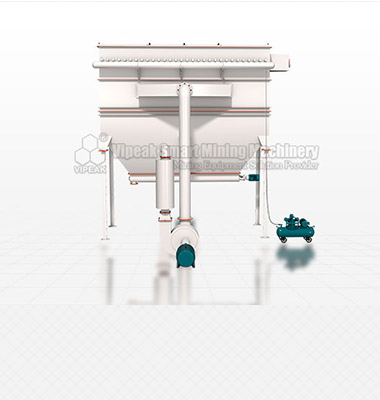

This project is mainly used to process the furnace bottom slag and fly ash discharged from Wuhan Iron and Steel (Group) Company (WISCO) self-provided coal-fired power plant.

The processed products can be widely used in embankment, concrete admixture, soil modification, cement, asphalt mixing station and other fields. Vipeak provided professional technical solutions and rich successful case support during the bidding process of WISCO's project, which won the customer's recognition and trust. The grinder grinds secondary ash with a capacity of 9t/h.

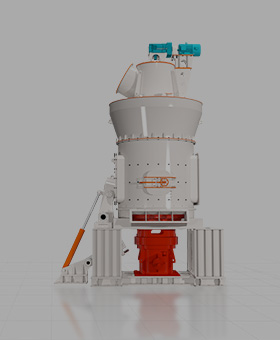

The raw materials in the hopper are transferred to the grinder by a quantitative belt feeder. The ground products are collected in the buffer silo and then transferred to the existing fine ash warehouse under the positive pressure of a silo pump. The grinding system is a closed-loop system. After the raw materials are milled, the mixed powder is blown by the wind of the blower, and then sorted by the built-in classifier. Fine powder is collected in the cyclone powder collector and coarse powder falls into the grinding chamber. The wind is separated from the top of the dust collector, and then returns to the blower for recycling. Part of the gas is purified by a bag filter and discharged into the atmosphere. The entire system is under PLC remote control.