This client has been engaged in the processing of oilfield drilling-grade barite powder for nearly ten years, and has long-term cooperative relationships with many oilfield system companies such as PetroChina and Sinopec.

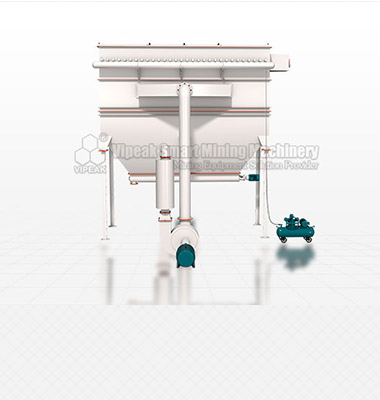

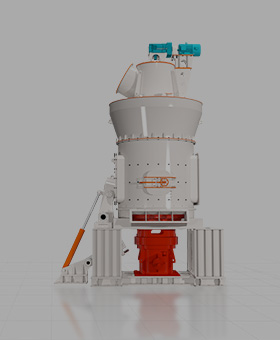

The grinder can achieve barite powder 200mesh(97% passing screen rate) with a capacity of 9-10t/h. The bucket elevator conveys the material to the storage silo, and then it is evenly sent to the grinder by the electromagnetic vibrating feeder. The material entering the grinder is lifted by the shovel and enters between the roller and the ring and is ground. The blower blows the air from the distribution disc into the grinding chamber, sends the pulverized powder to the classifier, and sorted by the rotating classifier impeller.

The fine powder enters the cyclone powder collector, and is separated from the air, and then discharged from the discharge port as the finished product. The qualified products are collected by a cyclone collector and then packed by automatic packaging machine. It adopts pulse bag dust collector and achieve dust-free operation on site.