EPC project general contracting refers to that the project contractor undertakes the design, procurement, construction, trial operation and after-sales service of the project according to the contract, and is responsible for the quality, safety, construction period and cost of the contracted project. It is currently promoted internationally The most important one among many general contracting models. This model is an extension of the general contracting business and responsibility of design, procurement, and construction. The ultimate goal is to be able to submit to the owner an engineering project that satisfies the function of use and has full use conditions.

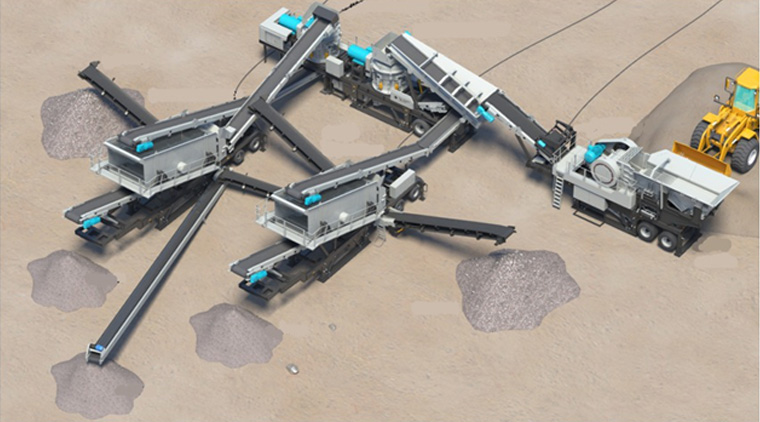

For the owners, choosing the EPC project can save you a lot of time and effort while saving yourself a lot of precious time. As a manufacturer of sandstone grinding equipment, it has made continuous progress in the development process. In order to meet customer needs, Vipeak introduced EPC project goes to the field of sand and stone milling to build a new platform for customers.

Why choose Vipeak for EPC project?

As a mine crushing, sand making, and grinding equipment manufacturer, Vipeak has experienced more than thirty years of development. During the development process, Vipeak has accumulated a lot of on-site experience and accumulated rich strength. These have also become Vipeak’s "Defeated".

1. Million flat production base

The factory area is the basic condition for equipment production and processing and a key link to ensure product quality. In order to achieve high-efficiency and high-quality processing and production of equipment, Vipeak arranges industrial parks in Jiaozuo Xiuwu, Zhengzhou High-tech Zone, Shanghai Lingang and other regions, and Standardized and precise production for crushing and grinding equipment, mobile station equipment and supporting equipment.

2. More than 600 sets of precision manufacturing instruments

Our company now has more than 600 precision manufacturing instruments, such as laser cutting machine, plasma cutting machine, carbon dioxide gas shielded welding, vibration aging instrument, 800T hydraulic bending machine, double-sided CNC horizontal milling and boring machine, CNC floor-type boring and milling machine automatic assembly Assembly lines, etc., ensure that every step from ingredient, welding, machining to equipment, painting, packaging can be perfect.

3. Responsive technical service and after-sales service

From pre-professional consultation and question answering to on-site inspection plan customization, from strict factory inspection to on-time delivery and delivery, from guided installation and commissioning to rapid maintenance response mechanism, the skilled service team is on duty 365 days a year, and the service has never been interrupted , never absent.

Advantages of the Vipeak EPC project

Among the numerous manufacturers of sand and gravel equipment, why must we choose Vipeak? The advantages of the Vipeak EPC project determine that Vipeak will definitely stand out from many manufacturers and attract your attention.

1. The investment risk is small and the workload is greatly reduced

The overall planning and specific implementation of the entire project will be completed by Veken's professional technical team, and the client is only responsible for the overall, principled and objective management and control. The contractual relationship is simpler than the traditional contracting model, the main body of responsibility is clear, all risks are greatly reduced, and the workload of the owner is greatly reduced.

2. Equipment selection, one-stop purchase

Vipeak focuses on the research and development and manufacturing of large-scale mining equipment. The equipment has large output, excellent quality, efficient and stable operation, and is environmentally friendly. It can meet the production needs of customers in the field of aggregates and industrial grinding.

3. Strong technical ability, professional design, clear positioning

Provide customers with a one-stop, complete set of professional solutions to solve the problems of customers, especially pure investment customers, with technical difficulties and little understanding of equipment, which makes the project's needs and positioning more clear, and arranges professional and technical personnel to design the solution And optimization, optimize production plans, and achieve overall construction arrangements.

4. Unified arrangement, convenient coordination, can greatly shorten the construction period

The design, production, installation, trial operation and other links are undertaken by our company to achieve full control of each link, which can be efficiently and uniformly arranged to facilitate coordination in all aspects, and project changes will be reduced accordingly, and the construction period will be shorter.

Do you now have a comprehensive understanding of Vipeak's EPC project? Then don’t hesitate to contact us! High-quality equipment and a full range of services are waiting for you!